The simple answer I thought was a new electronic distributor. Asking around the paddock at various hill climb meetings I got mixed reviews of such a change. Some said it was good and others said they reverted to the old one with points because of timing/starting issues.

I decided to buy one at the Austin Seven Guildtown Rally (as it was on offer) and had it fitted at the show. I went on a run with the device but I was plagued with misfires and lack of power at higher revs. The dealer offered to change the unit and in fact he tried another unit which had exactly the same charicteristics. I was fairly convinced it was due to the application in my car as numerous others had complete success, so I decided to purchase the unit on approval.

It is a nice looking part, I have taken it apart looking for the source of my problems and it all looks well designed and put together. I even tried using similar advance springs to my original unit. I put an Oscilloscope on the feed to the coil but I could not discern any abnormal behaviour in the waveforms. The Timing light when connected to the engine when running shows a random timing mark unsteady at any speed. The tick-over is rough. There is no appreciable mechanical slack in the drive to the distributor.

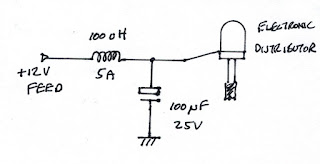

I had a eureka moment after competing at Forrestburn recently and decided the unit may be sensitive to noise from the generator/regulator. I have had problems in the past trying to put electronics in a car due to noise issues. In fact I had the same problem with my cooling pump timer. I decided to make a filter with a few bits lying about in my spares box. The theoretical cut-off frequency of the filter of this type is 1/(2*PI* SQRT(L*C)) in this case about 1.5KHz. It has a toroidal coil capable of 5A. The capacitor is an 12V electrolytic type so don't get it around the wrong way.

This completely cured the problems. These bits are readily available on either ebay or RS components.

|

| Before potting it in Silkoflex |

Here is an Index page for the build